Mesin paip HDPE

QINGDAO COMRISE MACHINERY CO., LTD.

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

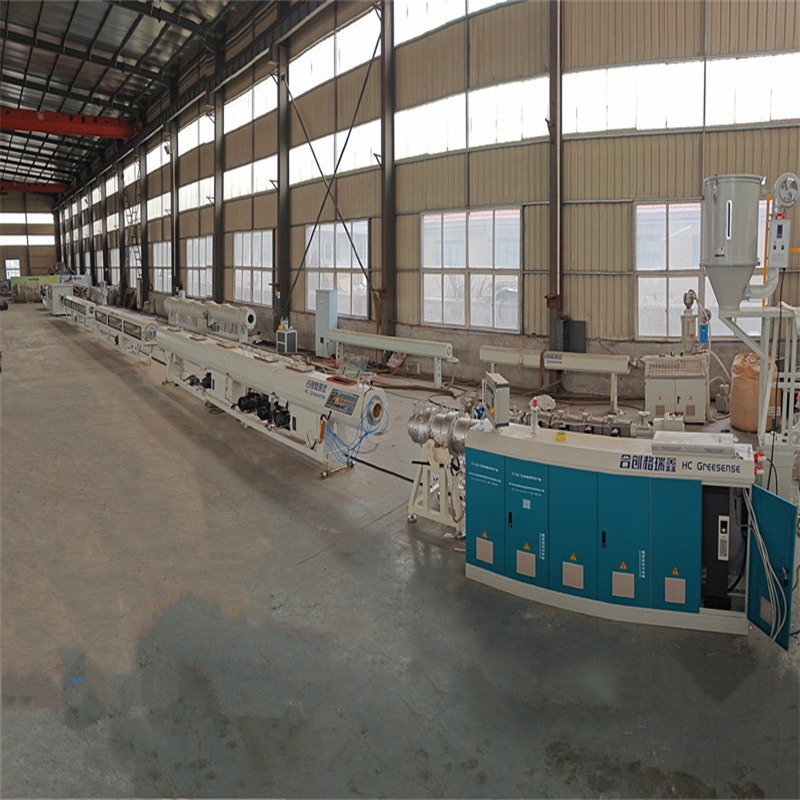

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

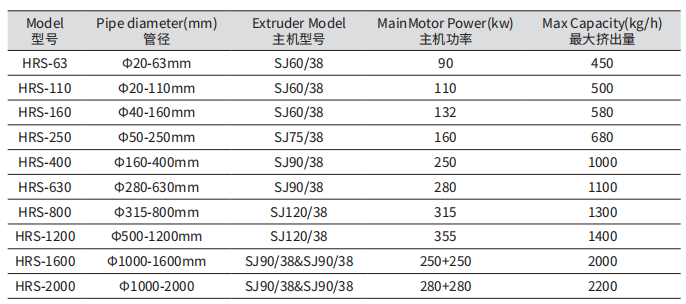

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

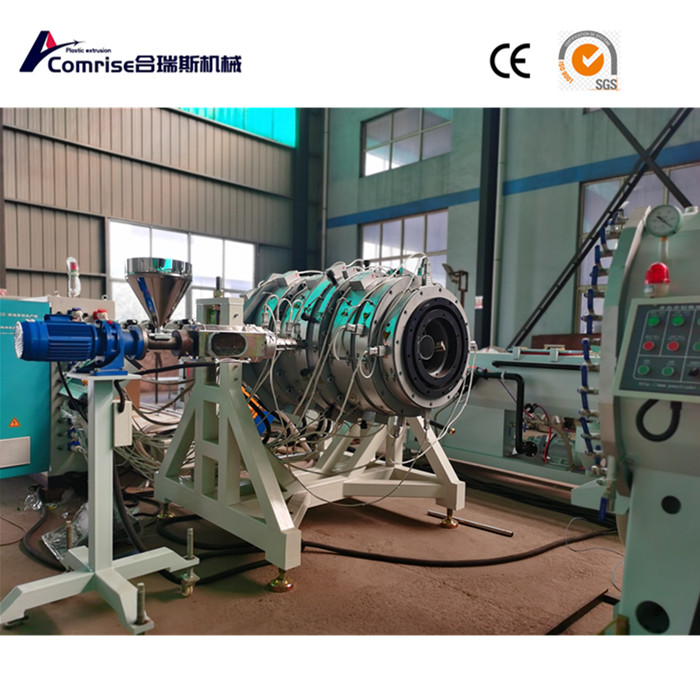

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

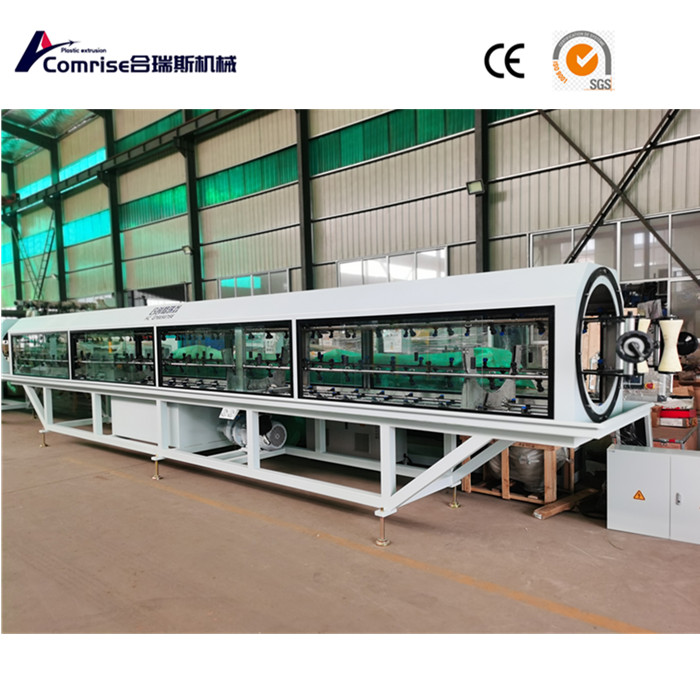

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

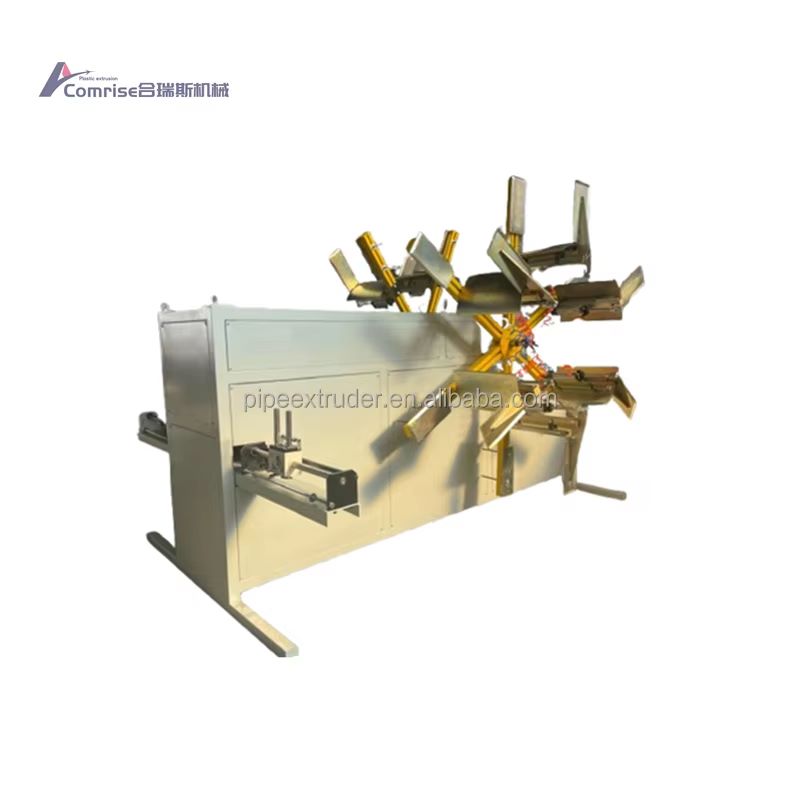

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

Mesin paip HDPE 110mm

Konfigurasi Mesin Mesin Kilang 110mm HDPE Konfigurasi Manfigurasi Mesin Berbeza dengan Julat Diameter Pipa yang Dihasilkan. Untuk pelbagai diameter kecil seperti 20-63mm, terdapat beberapa model kelajuan yang berbeza untuk pilihan, kelajuan pengeluaran tertinggi adalah sehingga 60m/min untuk paip HDPE 20 × 2.0mm. Barisan penyemperitan paip diameter HDPE besar boleh direka sebagai dua jenis pelepasan bersama atau 3 lapisan jenis pelepasan bersama. Koiler paip dilengkapi sebagai pilihan, untuk saiz paip gegelung dari 16-32mm, atau 20-63mm atau lebih besar sehingga 110mm.

Baca LagiHantar PertanyaanGaris pengeluaran mesin paip diameter besar PE

Kilang Jentera Comrise diameter PE PE PIPA PEAKA PETAK yang dihasilkan oleh garis ini mempunyai ciri-ciri kekakuan yang sangat baik, fleksibiliti, rintangan haba, rintangan penuaan, kekuatan mekanikal yang tinggi, rintangan keretakan tekanan alam sekitar, penentangan terhadap ubah bentuk rayap, rintangan kakisan dan hubungan panas, dan sebagainya.

Baca LagiHantar PertanyaanTiga Lapisan HDPE Co Extrusion Pipa Mesin

Paip Comreise PE biasanya digunakan untuk bekalan air bandar, pengangkutan gas asli dan gas, makanan dan industri kimia, pengangkutan bijih dan lumpur, penggantian paip simen, paip besi tuang, dan paip keluli. Pipa PPR digunakan secara meluas dalam bidang pembekalan air dan saliran air, bekalan air dan saliran di luar bandar, gas bandar, elektrik, dan sarung kabel optik gentian, serta dalam pembinaan, sektor perbandaran, perindustrian dan pertanian, pengangkutan cecair perindustrian, dan pengairan pertanian.

Baca LagiHantar PertanyaanMesin barisan pengeluaran paip HDPE

Mesin talian pengeluaran paip HDPE Comrise terutamanya digunakan untuk menghasilkan bekalan air dan paip saliran dalam bidang pertanian, pembinaan dan lain-lain. Mesin ini terdiri daripada extruder, acuan, tangki penentukuran vakum, dan peranti daya tarikan. Unit pemotongan, kren stacker dan unit tunggal lain Peranti extruder dan daya tarikan skru dilengkapi dengan peranti peraturan kelajuan frekuensi pembolehubah udara yang terkenal, dan pam vakum dan pam air kedua-duanya dari jenama terkenal. Peranti daya tarikan termasuk dua cakar, tiga cakar, empat cakar, enam cakar, lapan cakar, sepuluh cakar, dua belas cakar, dll. Mesin pemotongan bebas habuk, menyaksikan mesin pemotong bilah, atau mesin pemotongan planet boleh digunakan, dan prestasi unit boleh dipercayai.

Baca LagiHantar PertanyaanGaris penyemperitan paip HDPE

Comrise adalah garis penyemperitan paip HDPE China 110-315. Balut pelbagai lapisan atau lapisan gentian kekuatan tinggi seperti serat kaca dan serat poliester ke paip PE tulen yang sedia ada untuk membuat paip berfungsi, 110-315 garis penyemperitan paip HDPE. Tekanan meningkat kepada 4MPa. Seluruh barisan pengeluaran dikawal secara automatik oleh PLC dari penggantian bahan untuk menyusun, memastikan kebolehpercayaan Tinggi, mudah dijaga. Ciri -ciri cemerlang dalam barisan pengeluaran ini adalah bahawa ia bukan sahaja dapat menghasilkan paip PE tulen yang memenuhi piawaian antarabangsa. Ia juga boleh menghasilkan paip plastik komposit bertetulang dawai keluli.

Baca LagiHantar PertanyaanBarisan Mesin Pengeluaran Paip HDPE

Penyemperitan COMRISE HDPE HDPE Paip Pengeluaran Mesin boleh digunakan untuk menghasilkan paip PE diameter yang berbeza, dengan ketegaran dan fleksibiliti yang sangat baik, rintangan haba, rintangan penuaan, kekuatan mekanikal yang tinggi, ketahanan retak tekanan alam sekitar, rintangan deformasi rayuan, kaitan terma, dan sebagainya.

Baca LagiHantar Pertanyaan